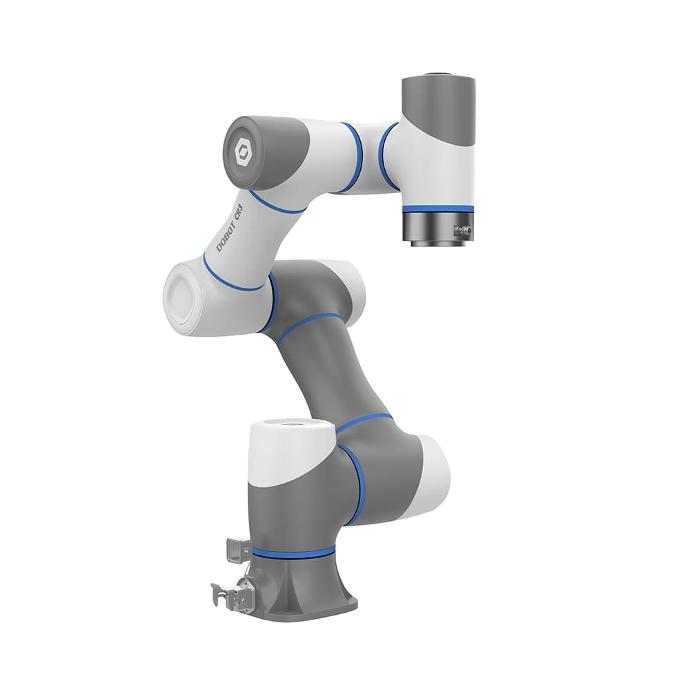

CR Series Collaborative Robots

The DOBOT CR Series consists of 6 payloads: 3 kg, 5 kg, 7 kg, 10 kg, 12 kg, and 16kg, with repeatability of ±0.02 mm. They are safe for human collaboration, easy to use, flexible and simple to deploy, making them ideal for a wide range of industries: automotive, consumer electronics, semiconductor, healthcare, chemical and new retail. The CR Series lowers labor cost while enhancing production efficiency.

Products

SafeSkin Innovative

Pre-collision Sensing Technology

Dobot’s exclusive technology for safer operations.

Easy to Learn.

Fast to Deploy.

Plug and play design allows a quick deployment using different accessories from our ecosystem. Program with graphical interface, scripting using smartphones, tablets and computers, or program directly with drag-to-teach. Complete installation in 20 minutes. Up and running in an hour.

Safe for Efficient Collaboration

The CR Series has 22 safety features built-in and is ISO 13849 and TS15066 certified. Equipped with sensors offering 5 adjustable levels of collision detection, it can adapt to a variety of application scenarios. The optional SafeSkin senses unexpected objects that come within 15 cm, actively enhances the safety and efficiency of the robot.

Infused with AI Technology

All-perceptive AI control technology combines vision, force, voice controls into one. Trajectory tracking and portable learning algorithm make imitating human hand motions possible.

Advanced Algorithm for Higher Performance

Industry-leading DH parameter compensation technology achieves ±0.02 mm repeatability. Vibration suppression and True Motion algorithms guarantee precision and stability during complex movements.

Open Ecosystem for Scalability

Various plug-and-play grippers, cameras, and sensors can be connected to multiple IO and communication interfaces on the robot. Secondary development is supported on 20+ development platforms. Task-specific software packages cover loading and unloading, assembly, screwdriving, polishing and other 50+ tasks that can be used across 8 major industries.

Application Scenario

Palletizing

Loading & Unloading

Assembly

Bin Picking

Gluing

Insertion

Polishing

Quality Inspection

Screwdriving

Specs

| Model | CR3 | CR5 | CR7 | CR10 | CR12 | CR16 | |

|---|---|---|---|---|---|---|---|

| Weight | 16.5 kg | 25 kg | 24.5 kg | 40 kg | 39.5 kg | 40 kg | |

| Maximum Payload | 3 kg | 5 kg | 7 kg | 10 kg | 12 kg | 16 kg | |

| Working Radius | 620 mm | 900 mm | 800 mm | 1300 mm | 1200 mm | 1000 mm | |

| Maximum Reach | 795 mm | 1096 mm | 990 mm | 1525 mm | 1425 mm | 1223 mm | |

| Rated Voltage | 48V DC | ||||||

| Maximum Speed of TCP | 2 m/s | 3 m/s | 3 m/s | 4 m/s | 4 m/s | 3 m/s | |

| Range of Motion | J1 | ±360° | |||||

| J2 | ±360° | ||||||

| J3 | ±155° | ±160° | ±160° | ±160° | ±160° | ±160° | |

| J4 | ±360° | ||||||

| J5 | ±360° | ||||||

| J6 | ±360° | ||||||

| Maximum Joint Speed | J1/J2 | 180°/s | 180°/s | 180° /s | 120°/s | 120° /s | 120°/s |

| J3/J4/J5/J6 | 180°/s | ||||||

| End-Effector I/O Interface | DI/DO/AI | 2 | |||||

| AO | 0 | ||||||

| Communication Interface | Communication | RS485 | |||||

| Controller I/O | DI | 16 | |||||

| DO/DI | 16 | ||||||

| AI/AO | 2 | ||||||

| ABZ Incremental Encoder | 1 | ||||||

| Repeatability | ±0.02 mm | ±0.02 mm | ±0.02 mm | ±0.03 mm | ±0.03 mm | ±0.03 mm | |

| Communication | TCP/IP, Modbus, Wi-Fi | ||||||

| IP Rating | IP54, Control Box IP20 | ||||||

| Temperature | 0° ~ 45° C | ||||||

| Power Consumption | 120W | 150W | 150W | 350W | 350W | 350W | |

| Materials | Aluminum alloy, ABS plastic | ||||||