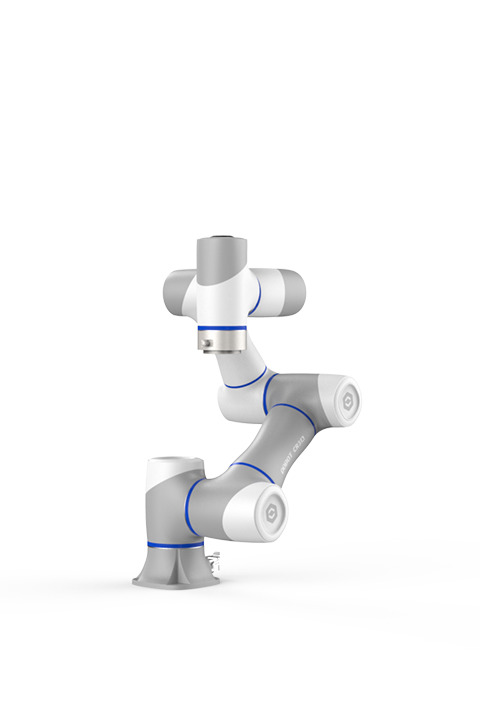

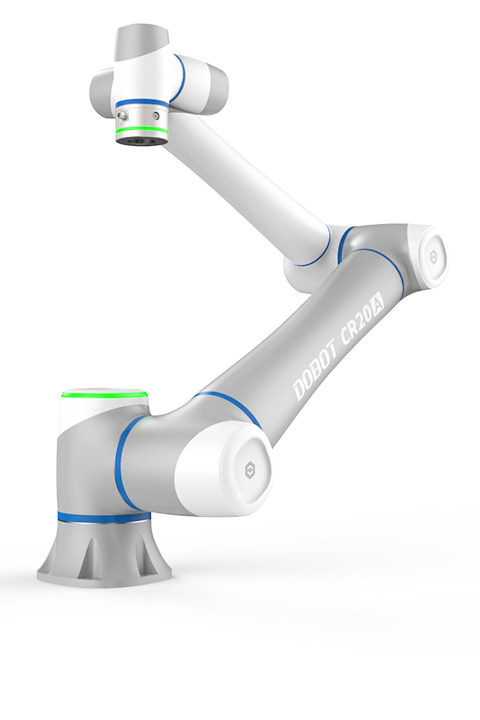

Dobot CRA Series Collaborative Robot

The new generation of CRA series redefines smart manufacturing. With high performance harmonic drive reducers, 25% cycle time improvement, these cobots take efficiency to a whole new level. By adapting the brand new control box and operating software, human-machine collaboration is brought to a new height in terms of safety, stability and expandability.

Products

SafeSkin

Innovative Pre-collision Sensing Technology

Dobot’s exclusive technology for safer operations.

Application Scenario

Welding

Palletizing

Loading & Unloading

Assembly

Bin Picking

Gluing

Insertion

Polishing

Quality Inspection

Screwdriving

Transporting

Reliable & Efficient

High performance harmonic drive reducers improve cycle time by 25%. Improved anti-vibration algorithm, optimal DH parameters compensation, and TrueMotion algorithm achieve 0.2 ~ 0.4 mm trajectory accuracy during complex movement.

Safe & Reassuring Collaboration

It is equipped with responsive electromagnetic brakes for safety. When there is a power outage, the brakes are engaged automatically within 18 ms, with a fall of less than 1 mm. It also supports the function of virtual boundaries, setting safety borders freely, with alert when borders are exceeded, machine deceleration and machine halt. Its end tool real-time payload detection ensures the safety of production, upgraded to 10 I/O ports to satisfy the safety requirements of external devices.

New Interface for Easy Operation

The 4th generation of DobotStudioPro has a good layout, making operation easy and efficient. The newly added environment simulation function allows calibration to be more straight forward. There are three programming methods: graphical programming, script programming and trajectory replay which can be controlled by PC computer, tablet, smartphone and teaching pendant.

2.5D Vision for Accurate Grabbing

Integrates 5-megapixel camera and LED light source with Dobot self-developed 2.5D spatial compensation technology, for applications such as grabbing slanted surfaces on objects and assembly for fixed positions and also transportation of AMMR robots and loading and unloading scenarios. The VX500 Smart Camera works with visualizable operation software, saves the hassle of development while being easy to deploy.

High Expandability

2 industrial grade Ethernet ports. Supports Modbus Ethernet/IP and Profinet communication. 24 I/O ports allow more external devices to be used.

Specs

| Model | CR3A | CR5A | CR7A | CR10A | CR12A | CR16A | CR20A | |

|---|---|---|---|---|---|---|---|---|

| Weight | 16.5 kg | 25 kg | 24.5 kg | 40 kg | 39.5 kg | 40 kg | 70 kg | |

| Maximum Payload | 3 kg | 5 kg | 7 kg | 10 kg | 12 kg | 16 kg | 20 kg | |

| Working Radius | 620 mm | 900 mm | 800 mm | 1300 mm | 1200 mm | 1000 mm | 1700 mm | |

| Maximum Linear Speed | 2 m/s | 2 m/s | 2 m/s | 2 m/s | 2 m/s | 2 m/s | 2 m/s | |

| Range of Motion | J1 | ±360° | ||||||

| J2 | ±360° | |||||||

| J3 | ±155° | ±160° | ±160° | ±160° | ±160° | ±160° | ±160° | |

| J4 | ±360° | |||||||

| J5 | ±360° | |||||||

| J6 | ±360° | |||||||

| Maximum Joint Speed | J1 | 180°/s | 180°/s | 180°/s | 150°/s | 150°/s | 150°/s | 120°/s |

| J2 | 180°/s | 180°/s | 180°/s | 150°/s | 150°/s | 150°/s | 120°/s | |

| J3 | 223°/s | 180°/s | 180°/s | 180°/s | 180°/s | 180°/s | 150°/s | |

| J4 | 223°/s | 180°/s | ||||||

| J5 | 223°/s | 180°/s | ||||||

| J6 | 223°/s | 180°/s | ||||||

| I/O Interface | DI | 2-way | 4-way | |||||

| DO | 2-way | 4-way | ||||||

| AI | 2-way (same as RS485) | 4-way (same as RS485) | ||||||

| AO | None | |||||||

| RS485 | Supported | |||||||

| Repeatability (mm) | ±0.02mm | ±0.02mm | ±0.02mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.05mm | |

| IP Rating | IIP54 | |||||||

| Noise | 70dB(A) | |||||||

| Temperature Range | 0 ℃ ~ 50 ℃ | |||||||

| Power Consumption | 120 W | 150 W | 150 W | 350 W | 350 W | 350 W | 500 W | |

| Installation Orientation | Any angle | |||||||

| Cable Length to Control Box | 5m | 5m | 5m | 5m | 5m | 5m | 6m | |

| Materials | Aluminum alloy, ABS plastic | |||||||