Flexible Automated Welding

Use Cobots to Accelerate Productivity,

Maintain Stability while Saving Cost

Challenges in Welding Processes

Inconsistent Quality & Safety

Manual welding, while prone to human errors affecting quality and material wastage, also poses safety concerns due to the lack of comprehensive safety measures in traditional automation, thereby increasing the risk of workplace accidents and injuries.

Limited Flexibility

Traditional welding equipment is restricted to narrow welding types, limiting its ability to meet custom production demands.

High Recruitment Cost

Welding requires proficient technicians, making the recruitment and training of skilled welders a challenging task.

Time-Consuming Deployment

Industrial robots are difficult to install and code. It relies on engineers for maintenance.

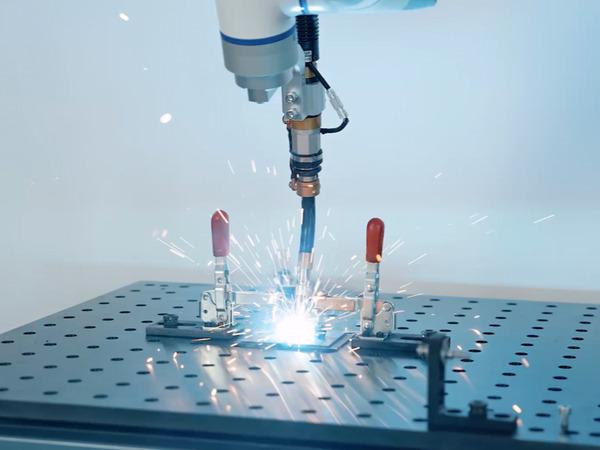

Dobot Automated Welding Solution

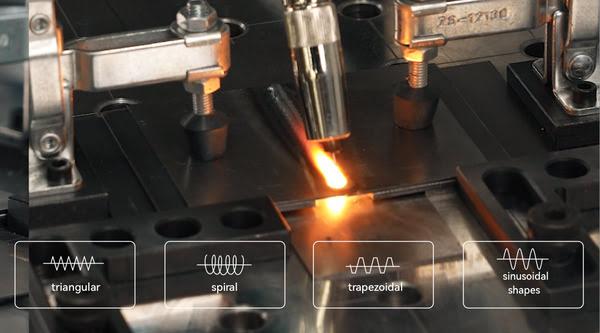

Dobot's exceptional professional welding process package facilitates the seamless integration of arc welding and laser welding applications, compatible with various mainstream welding machines and supports welding patterns, such as triangle, spiral, trapezoidal, and sine, ensuring a robust and versatile solution.

Shorter Deployment Time

With simple steps on the process package, the robot is compatible with various welding machine, saving deployment time.

Improved Quality & Productivity

Dobot's self-developed prevision control algorithms can achieve ±0.02 mm positioning accuracy for optimum quality and efficiency.

Safer Production Line

Dobot collaborative robots feature 5-level adjustable collision sensitivity, satisifies for diverse welding scenarios' needs.

Responsive to Various Needs

Dobot cobots can work flexibly in small areas, equipped with self-developed process packages, arc welding, laser welding solutions can be built quickly for different welding tasks for metal processing.